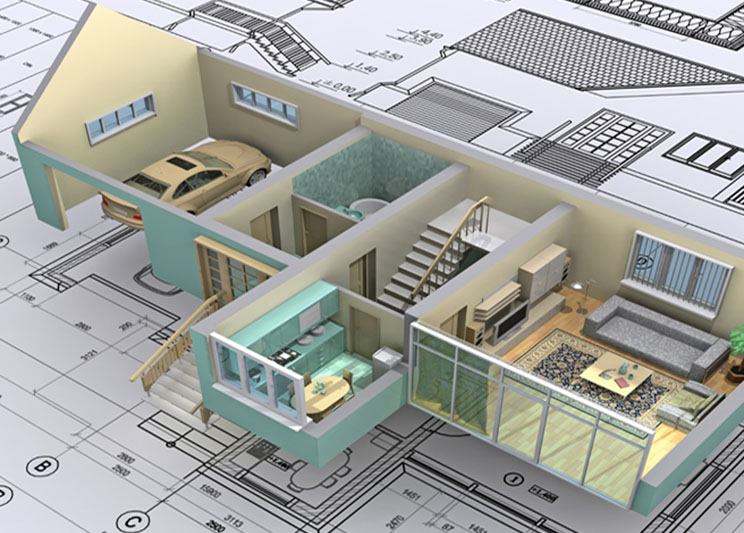

CONSULTANCY, DESIGN & ENGINEERING

We have established ourselves as leading providers of HVAC Consultancy, Designing & Engineering Services in the market at present. These are made available to the customers at industry leading rates. These are provided as per the set industry norms and guidelines. These services provided by us are to be fabricated using best suited inventory of raw materials available from all sources and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements.

WATER COOLED CHILLER SYSTEM

In many types of larger commercial and industrial buildings, water-cooled electric chillers offer an attractive alternative to air-cooled electric chillers and packaged rooftop units (RTUs). As their name implies, water-cooled chillers use water to absorb heat from the chiller and disperse it through a cooling tower, as opposed to air-cooled chillers and RTUs, which disperse heat only by using air-cooled condenser coils.

VRF/VRV SYSTEM

VRF systems are similar to the multi-split systems which connect one outdoor section to several evaporators. However, multi-split systems turn OFF or ON completely in response to one master controller, whereas VRF systems continually adjust the flow of refrigerant to each indoor evaporator. The control is achieved by continually varying the flow of refrigerant through a pulse modulating valve (PMV) whose opening is determined by the microprocessor receiving information from the thermistor sensors in each indoor unit. The indoor units are linked by a control wire to the outdoor unit which responds to the demand from the indoor units by varying its compressor speed to match the total cooling and/or heating requirements. VRF systems promise a more energy-efficient strategy (estimates range from 11% to 17% less energy compared to conventional units) at a somewhat higher cost.

INDUSTRIAL VENTILATION

Industrial facilities are often used in places that produce toxic airborne particles, hazardous chemical fumes, dust, and other harmful vapors. To mitigate the effect of these floating dangers, proper industrial ventilation needs to be installed. Put simply, industrial ventilation gets rid of the bad air and replaces it with fresh air from outside.

Ventilation is a necessary part of any industrial facility that will produce harmful air pollutants in a confined space where employees work. It not only cleans the air employees will breathe, it also allows for better temperature control and reduces the risk of fire in the facility. There are two main methods of industrial ventilation used to keep employees safe – dilution and local exhaust

DATA CENTER & SERVER ROOM COOLING

Nowadays, the term ‘Data Centre’ is a common term for many people. However, it is important to have a clear understanding of the concept in order to be able to understand the essential role that energy savings have in this type of facility. A data center is a specially conditioned space in which temperature and humidity are controlled; the electricity supply is stabilized and uninterrupted. There is structured cabling, control on access, security camera systems and fire detection and extinction systems, among other things. This is to contain all of a company’s IT systems and equipment.

COLD STORAGE SYSTEM

Stadco Heating & Air-conditioning provides cold storage solutions for warehouse/grocery stores, food processing facilities, warehouse distribution centers, and public cold storage. We design, build and service for varying project sizes.

An installation intended for the cooling, freezing, and cold storage of perishable food products and other perishables. A large cold-storage facility, which operates as an independent enterprise, comprises a cold-storage warehouse with truck and railroad platforms, compressor and condenser rooms for a refrigerating system, a cooling tower, reservoirs and a pumping station for a circulating water supply, administration and residential buildings, and other buildings and installations.

HOSPITAL/CLEAN ROOM & PHARMACY

Clean room technology and clean room management systems are found in many more areas than you may think, and not only in operating theatres, life sciences or semiconductor production. Clean room conditions are also needed in the Nano industry, in breweries, commercial bakeries, pharmacies, livestock facilities, in automotive engineering, and in control rooms and meeting rooms: in short, wherever the requirements of hygienic air and pressure control are high.

ROUTING SERVICE AND ANNUAL MAINTENANCE

Our Engineers & Technicians check proper maintenance of system components keep HVACs operating at peak efficiency-Implement a maintenance program to ensure that all components including Motors, Fans, Pumps, compressor, Ducting and filters are intact and working effectively.

Electricity Consumption can increase by up to 30 % if regular maintenance is not undertaken.